With the rapid growth of the food processing industry, the demand for frozen food market continues to grow. Increased consumer demand for convenient, high-quality food has made meatballs and other prepared foods a popular choice in the market. In response to this demand, the technology and production capacity of meatball processing lines are constantly being upgraded to ensure that meatballs can be produced efficiently and consistently to meet market demand.

Basic components of a meatball processing line

Meatball production lines usually include multiple stages such as raw material processing, mixing, molding, cooking, cooling and packaging. The meatball production process has a high degree of automation, which can greatly improve production efficiency and ensure food safety and quality stability. Firstly, the raw materials enter the mixing equipment after preliminary treatment, and mix well with the seasonings and auxiliary materials.

Next, the mixed minced meat is molded into standard meatball shapes through molding equipment. Then, the meatballs are processed by steaming or deep-frying to ensure that they are well cooked and have a good texture. Finally, the meatballs are cooled and packaged to complete the production process.

How to increase production capacity to meet market demand

In order to stay ahead of the competition, food manufacturers need to employ advanced Meatball Production Lines to increase capacity, optimize costs, and ensure product quality. Here are a few ways to increase capacity:

- Automate production: Adopting an automated meatball processing line reduces manual operations and increases production speed while ensuring consistent quality from batch to batch.

- Optimize production process: Rational planning of the meatball production process, including steps such as raw material handling, molding, cooking and freezing, reduces production bottlenecks and improves overall efficiency.

- Efficient freezing technology: The quality of quick-frozen food depends on the freezing process, and the use of rapid freezing equipment can maintain the taste and nutritional value of meatballs and improve market competitiveness.

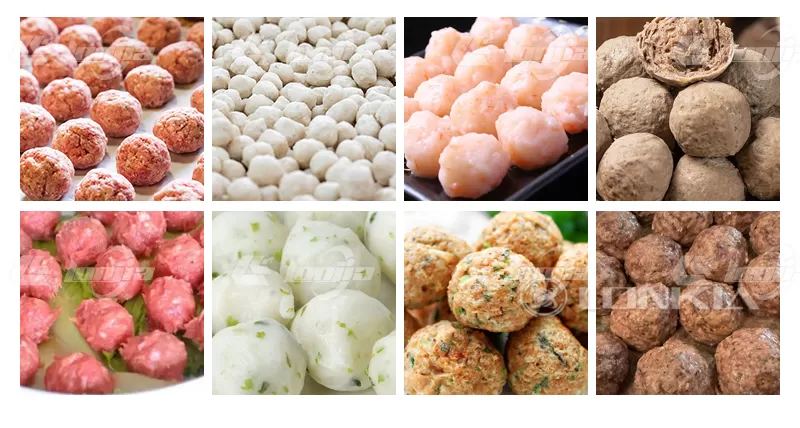

- Flexible production capacity: Different markets have different requirements for the taste, size and texture of meatballs, using adjustable meatball maker machine can meet the needs of different customers and expand the market scope.

Summarize

Meatball processing line plays an important role in meeting the demand of processed food market. Through continuous innovation and optimization of the production process, it not only improves production efficiency, but also ensures the quality and safety of meatball products. With the further development of technology, meatball production line will continue to occupy an important position in the food industry.